Edge of Dock Levelers | Loading Dock Plates | Loading Dock Leveler

Edge of Dock Leveler

A Safer Way to Bridge Gaps at Your Loading Dock

How to Use a Loading Dock Leveler / Dock Leveler Benefits / Edge of Dock Features / Dock Leveler Installation / Edge of Dock FAQs

What Is a Dock Leveler?

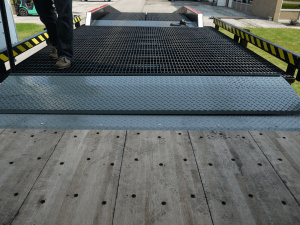

An edge of dock leveler (EOD) bridges the space between a loading dock and a truck or ramp. Unlike dockboards, edge of dock levelers are permanently mounted for quick, reliable access. Copperloy edge of dock levelers are built for seamless truck-to-dock transfers.

With a quick handle pull, the leveler rises above truck height for easy alignment. It mounts to most docks and comes in 66″, 72″, 78″, and 84″ widths. Each unit handles trucks 5″ above or below dock height, with 20,000 and 30,000 lb. capacities available.

This is the most cost-effective way to adjust for changing trailer heights—ideal when pit-style levelers aren’t an option. Safe, simple to use, and built to last, Copperloy edge of dock levelers are the smart alternative to dock plates—and your go-to solution from a trusted manufacturer.

Watch the dock equipment video below to learn more.

How to Use a Loading Dock Leveler

A loading dock leveler is a perfect solution for when dock space is limited, or when the working range of a full-size, pit-style edge of dock leveler is not needed. Each Copperloy edge of dock leveler is available with hydraulic or mechanical activation (lift) for smooth and reliable operation.

Simply pull back the handle and the lip will mechanically lift over the dock height. Then, a slight forward push of the handle will position the lip onto the truck floor. When you need to upgrade your loading dock equipment, consider edge of dock levelers to optimize your productivity.

All of our edge of dock levelers for sale are available with our quick, 3-day shipping. With loading dock equipment from Copperloy, you’ll get more done in less time, and increase your overall capabilities.

Top Benefits of Copperloy Edge of Dock Levelers

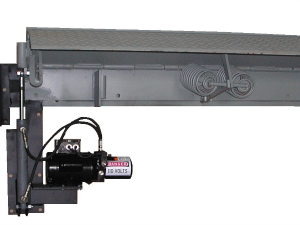

Copperloy edge of dock levelers are smooth and easy to operate. Whether using the handle or the wall-mounted push button (on the hydraulic unit) your EOD extends fully to the height of the trailer bed for safe freight handling. All the benefits of the mechanical system are also available in our hydraulic material handling warehouse dock leveler models.

Product durability: EODs are designed and engineered using a three-dimensional engineering software package.

Quick, easy lifting and positioning: Our exclusive lift mechanism and spring assembly sets the board in place with one-quarter the effort needed to operate conventional edge of dock levelers.

Push-button operation on hydraulic models: Easy operation will optimize your freight dock solutions.

Ideal for retrofit: The Copperloy edge of dock leveler easily mounts to the face of almost any dock. Transition plates and approach ramps are also available.

Safety: Every Copperloy edge of dock leveler is equipped with a safety maintenance strut to secure the unit while performing routine maintenance. Copperloy equipment is designed to meet OSHA laws and regulations to make your loading dock a safer place to work.

Low maintenance: Maintenance is reduced to simple lubrication of hinges which come equipped with grease fittings.

If you’re ready to upgrade your loading dock equipment, contact us today for more dock leveler details and learn about our edge of dock levelers price.

Warehouse Edge of Dock Leveler | The #1 Way To Stay Safe

A Copperloy edge of dock leveler is a great solution to make your loading and unloading dock safe. Not only is an edge of dock leveler for loading and unloading materials, but its innovative attributes are also designed to OSHA standards to keep your employees safe.

The warehouse edge of dock leveler should be installed into your facility’s designated loading dock to allow forklifts to move materials with a smoother transition. Not only does this allow for the forklift operators to stay safe, but it decreases the chance of damaging products and materials in the loading/unloading process.

An edge of dock leveler has many safety precautions to allow for simple and safe use. The safety maintenance strut is a feature that will secure the edge of dock leveler in place for routine maintenance checks. A warehouse edge of dock leveler is low maintenance, simple to operate, and an overall essential device to keep your work environment safe.

Edge of Dock Features

Loading Dock Leveler Specifications

High strength low alloy (50,000 lb. Minimum Yield) tread plate, lip beveled for smooth transition.

Projections

Bumpers 16″. Ramp 13 1/2″ in the stored position. The lip extends 12″ beyond the bumpers on standard lip models and 14″ on refer lip models.

Bumpers

4″ x 13″ x 10″ molded reinforced rubber mounted to the steel box frame. Optional 4″ x 12″ x 13″ bumper assembly.

Lift Assist

Dual extension springs.

Finish

The unit is completely cleaned, deburred and painted gray.

Service Range

Capable of servicing trucks 5″ above and 5″ below the dock.

Capacities

20,000 lb. and 30,000 lb.

Widths

66″, 72″, 78″, 84″

Options

Consult the factory for more information:

- Refer Lip

- Reduced Lip bend

- In-Board Handle Assembly

- Hydraulic Model – 115/230 VAC Single Phase

Dock Leveler Installation

For proper dock level installation, it is crucial the installer reviews the edge-of-dock manual and considers the precautions. Initially, it is the installer’s responsibility to evaluate the health of the dock area and make any necessary repairs.

All anchors must have a minimum strength in shear of 10,000 lbs force and a minimum of 6,000 lb pullout strength in uncracked concrete. The dock leveler must also comply with all local codes.

Consult with a member of our Copperloy team for a complete overview of the proper installment steps and the edge of dock leveler cost. Also, check out the video below and the owner’s manual for a list of tips! And don’t forget, you can expand your loading dock capacity too with our portable, mobile yard ramp.

Edge of Dock FAQS

Loading Dock Levelers | What You Should Know

Like any piece of equipment at a loading dock, an edge of dock leveler can be highly beneficial, but it will only work well if it is operated correctly, and safety can only be guaranteed if the safety guidelines are followed. Here are some important tips and factors to keep in mind as you activate and operate your edge of dock leveler.

Edge-of-Dock Dock Leveler Safety Precautions

Always |

Never |

|---|---|

| Ensure the trailer is backed in against bumpers before activating. | Exceed 5 mph when driving on the leveler. |

| Remove any end loads if required. | Exceed the rated capacity of the leveler. |

| Check trailer alignment to avoid lip interference. If lip does not lower to the trailer bed, be sure to reposition the vehicle | Travel on the leveler unless the lip is securely on the truck floor. There should be a minimum of 4” overlap onto the truck bed. |

| Chock truck wheels or lock the truck in place with a restraining device and set brakes. | Use this unit to service trailers outside its intended working range, which is 5” above and 5” below dock height. |

| Ensure that no equipment, material, or people are on the dock leveler before the vehicle leaves. | Use the dock leveler if it looks broken or if it is not operating correctly. |

| Return the dock leveler to its stored position. | Use the dock leveler if operating it causes undue physical strain or impairment. |

| Always keep both hands firmly on the hand leveler while raising or lowering, and keep other body parts clear |

For other safety precautions, reference our full manual.

Edge-of-Dock dock leveler Operation

Now that you have installed your dock leveler, it is finally time for the fun part – operating it. We have instructions for hydraulic operation in our manual. Here are some high points in regard to operating a non-hydraulic edge of dock leveler.

It is essential to reference all safety points before beginning to operate our edge-of-dock dock leveler.

Before operating a dock leveler, it is important to understand the basic concept of how this equipment is meant to work.

The edge-of-dock dock leveler is intended to bridge any gaps caused by height differences between a loading dock and a freight carrier. Filling these gaps makes for safer and more efficient freight transfer. Our mechanical edge-of-dock dock leveler is spring counterbalanced. The hand leveler is used to position the ramp and the lip onto the truck bed and also to return the dock leveler to the store position. The hand leveler also controls the lip extension link. Moving the lever forward extends the lip of the dock leveler onto the truck, and then off the truck after the load has been moved.

With those basics in mind, here are the steps required to operate a Copperloy edge-of-dock dock leveler.

Step 1: Wait until the truck is in the proper position against the dock bumpers. Doing anything prematurely can result in property damage and/or serious injuries.

Step 2: Alert the driver of the industrial vehicle that the truck needs to stay at the dock

Step 3: Chock or hitch the truck at that point.

Step 4: Remove the end loads once the dock leveler is in the stored position.

Step 5: Now it’s time to extend the dock leveler lip into the truck.

Step 5.1: Insert the hand leveler into the lever socket you’ll see on the right side of the ramp plate. Make sure you keep both hands firmly on the hand leveler while you are lowering or raising the dock leveler, and keep all other people and body parts clear. Never use legs or feet to move or hold the hand lever.

Step 5.2: Pull back the hand lever until the lip extender link is properly situated on the extender pivot bushing (for diagrams, please reference our manual).

Step 5.3: Raise the hand lever so that the lip extends as the ramp is lowered.

Step 5.4: Once the dock leveler is securely on the truck bed, the hand lever can be removed. Do not operate the dock leveler when anyone is on it or in front of it, and all personnel should stand clear while the dock leveler is moving. No one should walk or drive on the dock leveler or lip until it is fully extended and supported by the truck bed. Do not use a fork truck or any other material handling equipment to lower the ramp or the lip section. The dock leveler should be operated only as indicated here.

Step 6: The team can now load or unload.

Step 7: Once everything has been loaded or unloaded, the dock leveler can be returned to its stored position. The hand lever is reinserted into the socket on the right side of the ramp plate. Pull on the hand lever until the lip clears the truck bed. Once everything is in its stored position, the hand lever can be removed and the truck can be unchoked or released. Make sure the truck does not leave before the dock leveler is in its fully stored position. If the truck pulls away too soon, the lip will fall to the pendant position. The hand lever needs to be used to return the dock leveler to its proper position, or serious injury or death can result.

Step 8: Verbally alert the driver that the truck can leave the dock once everything is secure.