Loading Dock Ramps For Faster Loading

Stationary Dock to Ground Ramp Information

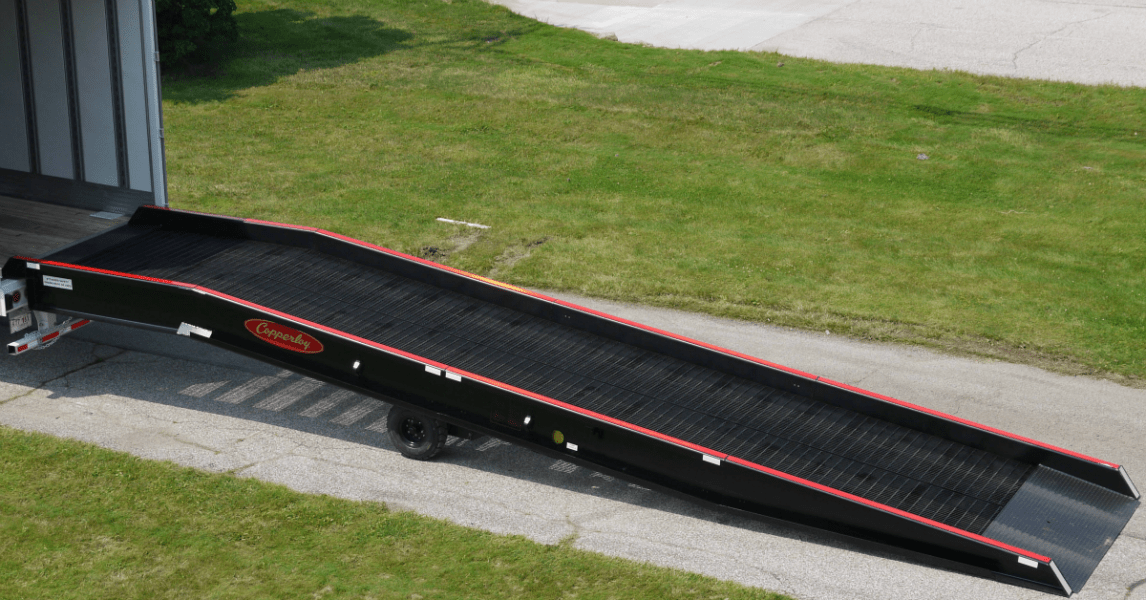

Stationary Loading Dock Ramps

Loading dock ramps are industrial solutions that bridge the gap between ground level and the raised floor of industrial or specialized facilities. These durable structures, entirely made in the US, fit seamlessly with any dock door, eliminating the need for costly permanent construction, and can be easily moved as your needs change.

Making Your Job Easier & Safer

Our stationary loading dock ramps have solved the common problems customers have faced with other manufacturers’ loading dock ramps in the past. Many facilities struggle with slow loading processes that waste time and money. Equipment often breaks down, resulting in costly repairs. Workers get injured using unsafe ramps.

Copperloy loading dock ramps have addressed these critical issues. The ramp’s durable construction reduces the frequency of breakdowns and repair costs. Our ramps are engineered for safety, with safety features like the 7″ safety curb and deck grating, protecting workers from common loading dock injuries. These improvements streamline operations, making loading processes faster and more efficient. Key performance features include the low-end plate, which creates smooth transitions and reduces impact on equipment. The 15-inch lip provides a secure connection to the dock and prevents dangerous gaps during loading operations.

Our loading dock ramps are engineered and built in our facility to deliver a long-term solution that provides lasting value for your loading operations. With quick installation and no permanent modifications required, you can start improving your productivity immediately while maintaining the flexibility to adapt as your business grows.

5 Safety and Performance Features

15” Safety Lip

Never worry about dangerous gaps again

Our 15-inch safety lip eliminates a significant cause of loading accidents. The lip flexes as loads move up and down, maintaining constant contact with your dock.

Stable Low End Plate

Ensure smooth loading

Our low end plate eliminates bumps when forklifts travel on and off the ramp with the beveled underside.

Traction Deck Grating

Stop slips when loading

Our deck grating provides superior strength and traction from the electro-forged serrated steel construction.

7 Inch Safety Curb

Prevent vehicle accidents

The 7 inch curb prevents accidental vehicle runoff.

Stability Chains and Brackets

Ensuring your ramp is secure to your dock

Chains and brackets are provided on every dock-to-ground ramp and secures the ramp to your loading dock.

Other Loading Dock Ramp Types:

Here’s What Our Customers Say

From William M. Petro, President of Century-Fournier Inc.

“I wanted to thank you for coordinating the pick-up, repair, and return to Metalico of the subject yard ramp in less than 24 hours. This enabled Metalico to continue operations with minimal downtime. Their management was very grateful for this turnaround.

We all want to sell our goods, be productive, profitable and be recognized for quality products and services, however, I believe the real test of a company’s fiber is how well it handles problems. JH Industries (Copperloy) has passed that test!

I’m sure there are many personnel that contributed to this successful repair. Please advise them how much we appreciate their contribution.”

Our Dock-To-Ground Ramps