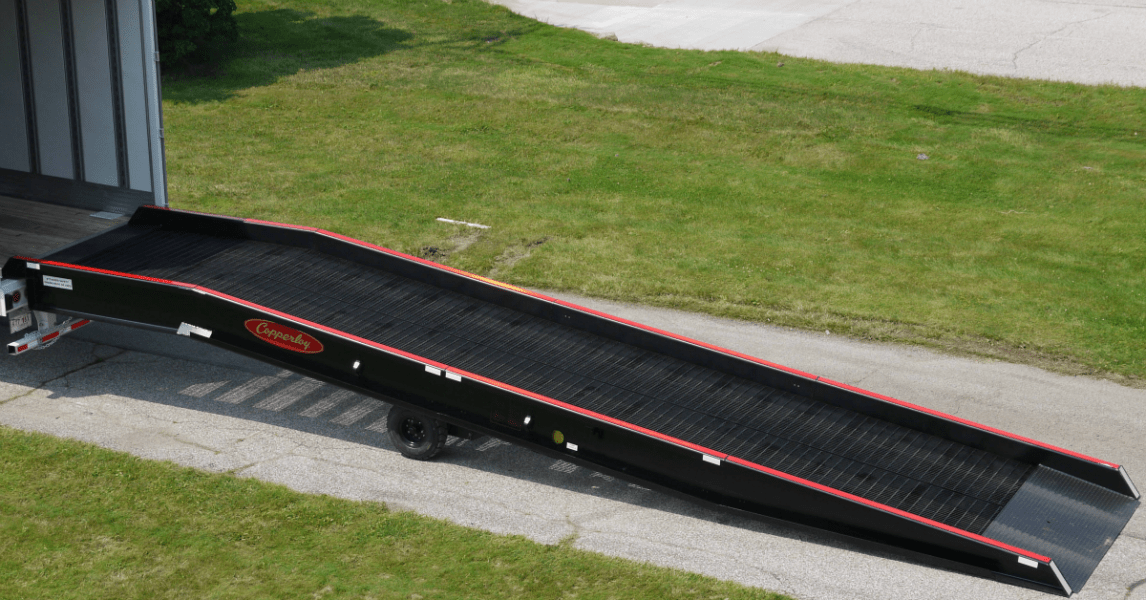

American Made Yard Ramps

Engineered for the Highest Speed & Forklift Safety with 10 Unique Features

Load/Unload Faster and Safer with a Copperloy Portable Yard Ramp

The steel yard ramp from Copperloy is designed to operate faster and with more safety features than any other forklift yard ramp. With our competitive pricing and short lead times, expanding your shipping capacity with mobile loading dock truck ramps has never been easier.

Unique Features for Speed & Safety:

- Steel or Aluminum I-Beam Construction

- 7” Steel Curbs / 7” Aluminum Curbs

- 36’ in Length

- 8’ Level-Off

- 30” Approach Ramp

- 15” Lip

- 1 ¾” Serrated Steel Grating

- 18” Solid/Pneumatic Tires

- Single-Acting Hydraulic Pump

- Positioning Sleeve (180° rotation)

- Safety Chains

- Tow Bar (optional)

Yard Ramp Details

Our Offerings

Applications of Yard Ramps

Semi Truck Loading

Streamline your operations and expand your loading capacity by using our yard ramps to load semi-trucks directly from the ground. This method bypasses the need for a permanent loading dock, significantly increasing efficiency and allowing you to utilize any open space for shipping and receiving.

Loading With Forklifts

When using a forklift, safety is paramount. Our yard ramps are engineered with features like high-traction deck grating to prevent slips and 7-inch safety curbs to protect against accidental runoff. Ensure your team and freight are as safe and secure as possible by utilizing our ramps.

Here’s What Our Customers Say

From William M. Petro, President of Century-Fournier Inc.

“I wanted to thank you for coordinating the pick-up, repair, and return to Metalico of the subject yard ramp in less than 24 hours. This enabled Metalico to continue operations with minimal downtime. Their management was very grateful for this turnaround.

We all want to sell our goods, be productive, profitable and be recognized for quality products and services, however, I believe the real test of a company’s fiber is how well it handles problems. JH Industries (Copperloy) has passed that test!

I’m sure there are many personnel that contributed to this successful repair. Please advise them how much we appreciate their contribution.”