Single Acting or Double Acting Hydraulic Ramps | Is Two Always Better Than One?

What’s the Difference? / Why is Single-Acting the Way to Go? / Why Choose Copperloy?

What’s the Difference? / Why is Single-Acting the Way to Go? / Why Choose Copperloy?

You want your yard ramps to be strong enough to handle almost any job, right? Hydraulic ramps offer high weight capacities as well as safe and stable operation. However, not all hydraulic ramps are the same. These systems vary depending on the type of hydraulic cylinders they utilize.

Hydraulic cylinders are incredibly common in industrial vehicles and machinery that perform tasks involving heavy lifting. Whether single-acting or double-acting, these hydraulic systems provide the strength necessary for safely lifting or supporting extremely heavy objects.

But doesn’t double-acting mean twice the strength? Well, not necessarily. Although single-acting sounds like the weaker option, it is just as strong a competitor as double-acting. Two is not always better than one.

What’s the Difference?

Before we can compare these cylinders, we need to understand how they work. Single-acting hydraulic cylinders are interesting because the fluid it uses applies pressure to only one side of the piston. As the fluid fills the cylinder, it extends the cylinder shaft and prevents the cylinder from pressing back down, resulting in movement. To return to its original position, it uses a spring or some other external force.

Double-acting cylinders are slightly different. Instead of filling on only a single side, it applies pressure to both sides of the piston. This allows it to both extend and compress the cylinder without any need for a spring or any device. Although this sounds more convenient, double-acting cylinders are reserved most often for tasks that require the application of extreme force.

So, how does this apply to yard ramps? Yard ramp designs can use either class of hydraulic cylinders, but why would you ever choose anything besides double-acting if it can apply more force?

Why is Single-Acting the Way to Go?

Copperloy prioritizes the single-acting hydraulic ramp design because its versatility and performance far outweigh the raw strength of double-acting cylinders. In fact, the simple single-acting cylinder design makes it useful in a wider range of tasks, but versatility is not the only advantage of Copperloy ramp design.

Copperloy prioritizes the single-acting hydraulic ramp design because its versatility and performance far outweigh the raw strength of double-acting cylinders. In fact, the simple single-acting cylinder design makes it useful in a wider range of tasks, but versatility is not the only advantage of Copperloy ramp design.

Quick Raise Times & Easy Setup

Double-acting cylinders push harder. Naturally, that would mean they are faster, right? Actually, in order to push harder, double-acting cylinders need much more pressure to operate, and generating that pressure takes time.

Single-acting hydraulic ramps do not need all this extra pressure, so they can raise up to two-and-a-half times faster. This means you can set up your ramp and get to work more quickly instead of waiting and waiting for a double-acting hydraulic ramp to reach the desired height.

Rising faster is not the only way Copperloy ramps save you time. Our unique ramp design allows you to link your ramp directly to the dock or truck. The hand pump is also on the outside of the ramp, so you can quickly start raising the ramp as soon as it is in position.

Meeting OSHA Requirements with Numerous Safety Features

Safety is always a priority when designing hydraulic ramps. Your forklift operators need a ramp that ensures their safety as they carry pallets on and off the truck. Forklifts alone already introduce a variety of safety hazards to both operators and other employees, so you do not want your yard ramp contributing to the problem. Here at Copperloy, we design our ramps to meet safety standards to prevent potential accidents and protect workers.

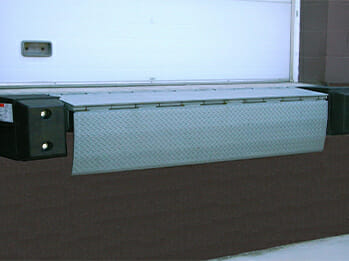

Our centrally-located, single-acting hydraulic ramp design offers stability even after positioning the ramp. This cylinder also prevents wobbling and tipping, ensuring forklifts have a smooth ride up and down the ramp at all times. We reinforce this stability by including a safety curb, high-traction deck grating, a low endplate, and an 8-foot level off. These features in combination with the single-acting cylinders make Copperloy ramps the safest option on the market.

Double the Action, Double the Size

Choosing the best yard ramp for your facility requires many dimensional considerations. Your ramp needs to be able to move through your facility space comfortably and efficiently. If your ramp ends up being too large, it will not be able to access all areas of your facility, and it will take much longer to move between tasks.

Double-acting cylinder systems are much larger than their single-acting counterparts. This also means double-acting hydraulic ramps are much larger, making them less functional and convenient. Single-acting cylinders are simple and compact, so we can more accurately design our ramps to meet the spatial needs of your unique facility.

Minimal Maintenance Requirements

The single-acting hydraulic cylinder design is much less complicated than double-acting cylinders. The cylinder only applies pressure in a single direction while a spring handles movement in the opposite direction. Not only does the simple design leave less room for errors and breakdowns, but it also makes the ramp more stable overall. A single-acting hydraulic ramp will raise more evenly than double-acting ramps, minimizing wear and tear and preventing downtime.

Protecting Your Wallet

One of the most obvious differences been single and double-acting cylinders is cost. Single-acting hydraulic cylinders are significantly cheaper to acquire and install. This allows us to minimize manufacturing costs on our end, but more importantly, lower manufacturing costs mean you pay less for your ramp at the end of the day.

The initial cost is not the only way you will save money, however. The low maintenance requirements and exceptional efficiency of single-acting hydraulic ramps ensure you get the most work done in the least amount of time. A single-acting Copperloy ramp will pay for itself in no time by maximizing productivity while minimizing downtime and repairs.

Why Should I Choose Copperloy Over Other Manufacturers?

So, single-acting hydraulic ramps are clearly the better choice, but why choose Copperloy? Why not seek out other hydraulic ramp manufacturers? Copperloy has been a leading designer and manufacturer of yard ramps and other loading equipment solutions for over 70 years. Our team of engineers uses state-of-the-art equipment to create ramps with superior strength and longevity.

If you need a ramp that meets high performance and safety standards, you cannot go wrong with Copperloy! Still not sure if Copperloy is right for you? Check out the video below to see how our ramps outperform the competition: