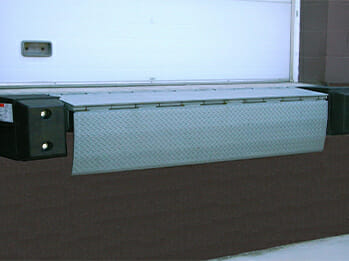

Loading Directly to Semi-Trucks With Reliable Ramps

The Forklift Operator’s Dream Come True

Our semi-truck ramps are the best way to improve workflow, safety, and productivity for loading! Copperloy is an American-owned and operated manufacturer and a leading provider of loading dock equipment solutions. We design ramps for superior quality and performance, so loading operations can stay on task and meet their quotas by loading directly to a semi truck from the ground.

If you are looking for a semi-truck ramp for your facility, we offer new, used, and rental models.