Dock Board vs Dock Plate

Dock Board vs Dock Plate | Similarities and Differences | Which One Best Fits Your Application Needs

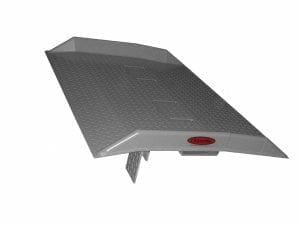

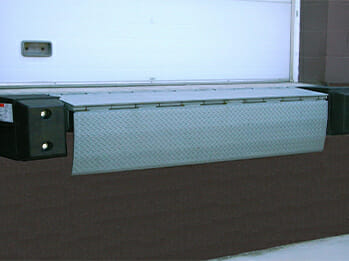

Here you can see the difference between a dock board and a dock plate. The dock board has curbs, where the dock plate does not.

Understanding the differences between dock boards and dock plates is essential for optimizing workplace safety and efficiency. While they may look similar, selecting the right option ensures your application needs are met effectively.

Dock Boards | Key Features | Pros & Cons

Dock boards are ideal for heavy-duty loading and unloading tasks, providing a secure bridge to address safety concerns. They are specifically designed to handle forklifts and other material handling equipment with ease.

Copperloy offers a variety of dock boards to meet diverse operational needs, including steel boards with welded curbs, aluminum boards with bolt-on steel curbs, and aluminum boards with welded curbs. Additionally, Copperloy can customize dock boards to match specific requirements, address unique challenges, or seamlessly integrate with existing equipment and spaces.

Key Features:

- Copperloy offers 3 options to choose from

- Handle capacities up to 20,000 pounds

- Made of Steel or Aluminum

- Strong, durable, and built to withstand high capacity

- Mobility For Your Investment

- Safety For Your Workers

Pros:

- Creates a bridge gap between trailers and loading docks

- Designed for use with forklifts and power jacks

- Option to lock to trailer and dock

- Flat surface with a slight level off

- Side Curbs to prevent runoff and provide additional strength and stability when handling heavier weight capacities

- Easily relocate with forklift assistance

- Carrying chains and or cutouts for forklift transportation

Cons:

- Heavier than dock plates (requires a forklift to move)

- Slow placement and removal between shipping/receiving

- Must be inspected on a regular basis for cracks and wear

- Must be used in the correct application; both length, width, and capacity are very important

Dock Plates | Key Features | Pros & Cons

Dock plates are very much like dock boards, but do not have curbs. These are used to bridge a gap from one area to another in material handling operations. However, unlike dock boards, dock plates are a flat piece of metal with a slight bend for an easy transition. Dock plates come in either steel or aluminum and can reach capacities up to 17,000 pounds. Interestingly, the extra capacity that dock boards are able to achieve comes from the structural addition of curbs.

Key Features:

- Handles that Allow for Easy Movement

- Designed for lighter equipment – hand carts, pallet jacks, foot traffic

- Aluminum

- Constructed with a locking leg

- Cost-effective compared to Dock Boards

- Safety For Your Workers

Pros:

- Locking legs underneath to prevent shifting during use

- Creates a bridge gap between trailers and loading docks

- Typically made of aluminum

- Inexpensive

- Lighter-weight than a dock board, two people can move it

- Flat surface w/ slight level off

- Most have handles

- Easily Storable

- Rust-free

Cons:

- NOT INTENDED FOR USE WITH POWER EQUIPMENT

- Must be used in correct application; both length, width, height, and capacity are very important. Most do not lock to the dock or trailer with pins.

So when it comes down to dock board vs dock plate, you need to consider what you will be using your dock equipment for? If employing a forklift, a dock board would be your best fit. If employing hand trucks and hand pallet jacks, then a dock plate would be your best fit. With the correct dock component, loading and unloading become more efficient, and your employees will be better protected from accidental falls.

Custom Dock Boards and Dock Plates

Copperloy offers custom dock boards and custom dock plates to meet any requirement or unique challenge. Our custom manufacturing and fabrication team can engineer exactly what you need from start to finish! You can read about a custom rail board we did here.

When it comes to safe material handling, Copperloy’s inventory does not end at dock boards and dock plates. We offer customers a wide variety of American-made mobile yard ramps that provide a loading and unloading facility where one isn’t already established. This wide range of equipment includes mobile yard ramps, dock-to-ground ramps, truck ramps, forklift ramps, and portable yard ramps.

Learn more about what Copperloy can do for your material handling needs by calling us directly at 800-321-4968 or clicking here and filling out the form.

About Copperloy

If you are looking for dock boards, dock plates, or any other type of loading dock equipment, you can trust Copperloy to deliver the solutions you need. For over 70 years, Copperloy has been a leading provider of high-quality, durable loading dock equipment, helping countless facilities maximize safety and efficiency.

Here is what sets Copperloy apart from other loading dock equipment manufacturers:

- State-of-the-art manufacturing facility operating computer numerical control (CNC) and high-precision robotic technology.

- In-house engineering staff that thoroughly reviews each project to ensure structural integrity and a proper design for your application.

- The technical sales department works with our engineering and the client throughout the design and manufacturing process to ensure the final product meets your unique requirements.

- Products designed and manufactured in the USA.

Most importantly, Copperloy offers the tools and experience necessary for transforming your workspace and meeting your needs. Consider our ultimate yard ramp to speed up production. You will always receive the best equipment solutions on the market, tailor-made to your specifications. So, you can elevate your operation to maintain ideal levels of safety, productivity, and profitability. Get in touch with Copperloy today and send us your CAD drawings, and we can get to work on your new, custom loading dock equipment and yard ramps.