Dock Boards and Bridge Plates | Loading Dock Equipment

Dock Boards and Bridge Plates | Knowing the Difference

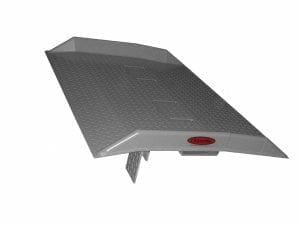

Here you can see the difference between a dock board and a dock plate. The dock board has curbs, where the dock plate does not.

Looking for dock boards or bridge plates but not quite sure which one would be best suitable for your loading and unloading requirements? Knowing the differences between dock boards and bridge plates is easily confusing and we strive to keep our customers informed. Though they look very similar, they have a unique design for their different levels of usage. Our goal is for your loading dock to function safely, efficiently, and productively.

Copperloy Dock Boards

- Capacity: Up to 30,000 pounds

- Operated With: Heavy-duty Equipment such as forklifts

- Construction: Steel or Aluminum with 3 Options available

- Weight: Heavier than Bridge Plates

- Maneuverability: With Forklift

- Additional Special Features: Increased strength for maximum durability and security. Moving chains and lifting loops. Curbs on both sides to prevent runoff.

Dock Boards – Used for heavy-duty applications to load and unload material with forklifts and other material handling equipment. Copperloy offers dock boards in 3 options – steel, aluminum with bolt-on steel curbs, and aluminum with welded curbs. Dock boards provide a safe passway between dock and truck during loading and unloading applications. Additionally, dock boards have a capacity of up to 20,000 pounds and an added feature of curbs designed to prevent loading equipment from running off the edge.

Copperloy Bridge Plates

Capacity: Up to 17,000 Pounds

Operated With: Hand trucks, Pallet Jacks, Foot Traffic

Construction: Aluminum

Weight: Lighter than Dock Boards

Maneuverability: One or two people can move these, comes with standard lift staps.

Additional Special Features: T-bar legs to prevent the plate from moving out of place.

Bridge Plates – also known as dock plates are extremely similar to dock boards minus the curbs and not recommended for heavy-duty applications and powered material handling equipment such as forklifts. Spanning the gap between dock and truck during applications, recommended being used with a pallet jack and or hand trucks. Bridge plates offer more of a flat surface with a slight bend for an easy transition from dock and truck.

Additionally, bridge plates come in steel or aluminum and have capacities of up to 17,000 pounds with locking legs underneath that slip directly into the gap between dock and truck to prevent any shifting. Copperloy’s bridge plates also feature an embossed diamond surface to prevent any wheel and or foot slip during use. Bright yellow safety stripes on the edges for high-visibility guidance during operation.

What Dock Loading Equipment Does Your Facility Employ?

Basically, the decision comes down to what type of equipment your facility employs on a daily basis. If you mostly move pallets from dock to truck with a pallet jack, a dock plate will meet these requirements. However, if you will need to occasionally load a heavier pallet with a forklift then you should invest in a dock board. Dock boards will function with either application.

If your facility has unique application requirements our in-house engineering team can custom manufacture dock boards and bridge plates in any special order configurations including any specification, size, or requirement. Contact Copperloy with custom design requirements. And you gain the security of knowing your heavier applications will be handled.

All of Copperloy’s loading dock equipment is manufactured in the USA.

Learn more about what Copperloy can do for your material handling needs, by calling us directly at 800-321-4968 or clicking here and filling out the form.

Custom Dock Board and Dock Plate Design Services

Not all loading dock equipment is created equal, and not every piece is going to work for every facility. So, you need to ensure the equipment you purchase will maximize your facility’s productivity. Here at Copperloy, we offer custom design services to develop the ideal dock boards and dock plates for our customers. In fact, our team has created a wide variety of custom loading dock equipment solutions including yard ramps, dock-to-ground ramps, lift tables, dock boards, dock plates, and more!

Every freight loading facility has its own set of needs, so we want to design our dock boards and dock plates to fulfill the unique requirements of every client. Therefore, we work closely with each customer to get a full understanding of what they need, allowing us to develop the ideal piece of equipment. For example, we can give our customers access to a full range of materials options including specialty steels, extruded aluminum, plastic, beryllium copper, and many more!

Choosing Copperloy means you will receive high-quality, custom dock equipment designed by expert engineers, so you can maintain optimal levels of efficiency in your facility and save money in the long run. Contact Copperloy today and send in your CAD drawings, so we can start working on your custom equipment solutions and yard ramps.